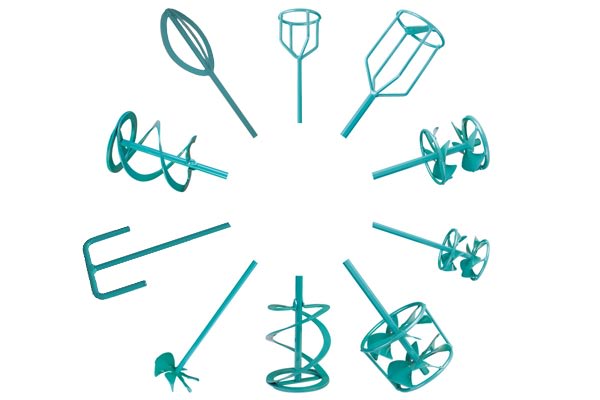

Matching the Correct Mixing Paddle to Your Material

With so many different materials being used these days for building purposes, users are becoming increasingly aware of how important it is to prepare the materials correctly. A decision as simple as the wrong choice of mixing paddle can result in a failure to homogenising a mix, a failure to activate the chemistry of a product, lost time and money mixing and lead to expensive repairs from mixing failures.

Paddle geometry is critical and your decision should be based on two factors: Mixing volume will determine the diameter of the mixing paddle, while the kind of material will determine its geometry.

There are three categories of mixing actions:

1. BOTTOM UP (POSITIVE ACTION)

The material is conveyed upwards through the middle of the mixing paddle from the bottom of the bucket and flows down again at the sides. This method should be used for powdery and dry mixtures.

2. TOP DOWN (NEGATIVE ACTION)

The material is forced down from the top and then flows back up again at the sides. Any lumps are broken up by the high force generated by the drive and the user, without splashing. This method is ideal for thin-bodied materials such as paints, dispersions, materials containing fibres, and gypsum plaster.

3. PARALLEL MIXING ACTION

The material is swirled on a single plane, the components only flow up or down when the mixing tool is moved accordingly. The suction effect results in optimal mixing results. This method is ideal for fillers. Fewer air inclusions in the material and, as a rule, higher shear forces, prevent the formation of lumps.

To take the confusion out of picking a paddle, get your free mixing paddle selection matrix from CE Construction Solutions.

Article Source: Collomix.com