What Is Concrete Maturity?

Maturity is a non-destructive approach to concrete testing which allows you to estimate in real time the early-age and compressive strength of in-place concrete. Using the maturity method, many projects greatly improve their schedule because it eliminates the need for concrete cylinder break tests.

The maturity method ASTM C1074 describes the methodology as “a technique for estimating concrete strength on the basis that the different concrete mixture samples achieve the same strength if they achieve the same index value.”

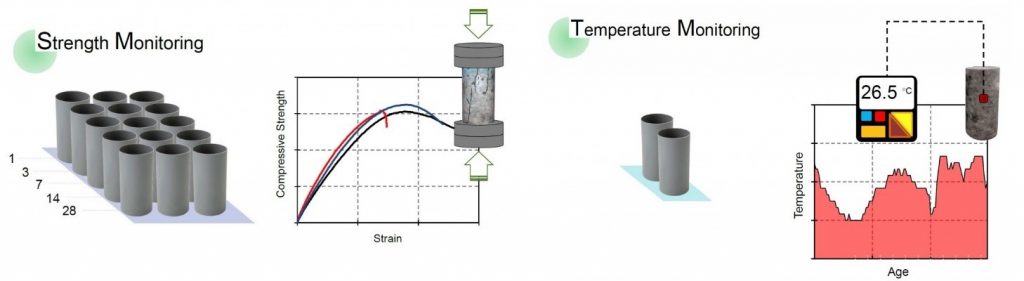

This development represents the progress of concrete curing. The index maturity value takes into account the temperature and curing time of the concrete. In order to implement this concept in a project, mix calibration is required. The aim of calibration is to determine a maturity-strength relation for a particular mix.

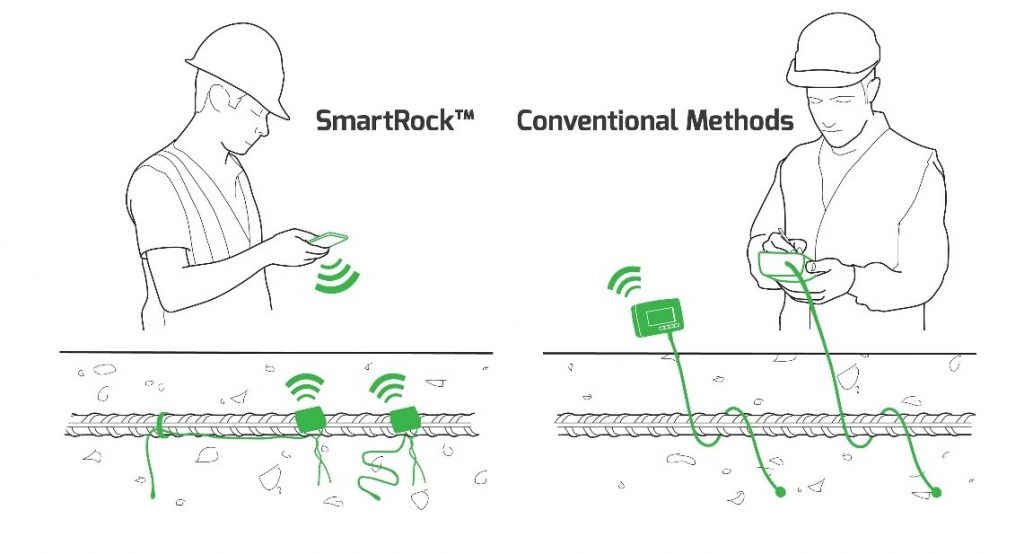

This data can be collected using a concrete maturity sensor. The sensor tests the concrete temperature and determines the strength / maturity of the concrete via the previously entered calibration data by the user. This substitutes break testing. The use of bulky wires is avoided by wireless maturity sensors such as SmartRock. It can also connect to any smart mobile device and instantly transfer data without using an often-costly data logger.

Figure 1 Example of materials needed for calibration process. Photos by Giatec Scientific Inc.

Comparing Break Tests and Maturity Sensors

If strength measurement data is unreliable, structural integrity is at risk. This shortens the life cycle and reduces the strength of the concrete mass element. That is why it is crucial to receive accurate and timely data that will allow construction workers to move forward with the removal of forms and post-tensioning. Although the use of break tests has been common practice in the construction industry for decades, it does not mean that this is the most accurate and reliable method for obtaining strength data.

An effective strength measurement in early construction has contractors either waiting too long for shaping, which is often due to project completion delays, or acting prematurely when removing concrete formwork– contributing to potential reliability and performance problems.

Using wireless sensors on site, contractors can collect more precise data and ensure their construction is secure, effective, and reliable. Information is collected by the embedded sensors which measure the temperature and strength of the concrete in real time.

Why Switch to the Maturity Method

Once on a job site, engineers want as much knowledge as they can have/get to help direct their decision-making during a project’s duration. In the first week in most building sites field-cured concrete samples are checked for strength at various ages to determine when to extract formwork. Typically, if the break tests indicate that the concrete exceeds 75 percent of its designed strength, formwork is removed, and the project moves on.

One of the issues is that cylinders undergoing a break test have a much smaller diameter, relative to the structure or slab on the spot. As a result, less moisture than in the actual structural product is retained, making the specimen not inherently indicative of the strength in place, also causing low breaks. In fact, when the break test specimens are being shipped to the third-party laboratory, the construction team stays on the job site waiting for sample results, adding additional labour costs.

Comparatively, the idea of maturity is a consistent method, as a non-destructive assessment strategy, which can remove guesswork. Other on-site non-destructive methodologies used to assess strength are also less reliable than experience, such as the Schmidt Hammer or Ultrasonic Pulse Velocity techniques. The maturity equation will determine the compressive strength of the whole system in an objective and quantitative calculation more accurately, until the maturity curve is determined by the concrete mix calibration.

Improving Jobsite Productivity with the Maturity Method

The common practice of cylinder break tests is not exactly accurate and reliable. Using the maturity method allows project managers to improve efficiency on the jobsite.

Maturity sensors will offer engineers real-time data which can be accessed on any mobile device and distributed across the cloud to all team members. The ability of the sensors to provide fast results allows for on-site decision-making to be well informed and efficient. Also, the cost of research and supplies reduces significantly, without having to wait for reports from cylinder break tests. It also removes the need to use a research facility for third parties.

Distinguishing Wireless and Wired Sensors

Wireless Sensors

The tool is completely mounted onto the rebar before pouring with a wireless maturity sensor. The installation with no protruding wires is simple and hassle-free. The data is collected on a mobile device or tablet through a wireless connection. It does away with the need for a data logger. With SmartRock, the sensor-gathered data is updated every 15 minutes and uploaded to the iOS or Android app. These data, as well as measurements given during mix calibration, are used to determine the in-situ concrete’s maturity/ strength in real time. This data can be quickly shared with team leaders, too, using the SmartRock app.

Wired Sensors

To collect this data, it takes costly data loggers to use wired temperature and strength sensors. Every wire is connected to a sensor and the measurements with loggers are taken by the person. It also leads to damage or cutting of wires. In addition, the loggers must stay at the site, where exposure to humidity can easily harm them. The wire is collected at one location for quick access when measuring temperature in various locations for

In addition, the montage of thermocouples calls for some detail! If not properly done, wires will cross the plug and cause errors of reading. Once the data is collected, this information must be transferred to a computer, like a laptop or a desktop, where an experienced person has to evaluate it. Depending on practice, it may take considerable working hours.

This article was written by our distribution partner Giatec on maturity testing for use with the SmartRock sensors.